Air Leak Tester is the automatic leak detector detects any leaks by the minute change of differential pressure and conducts OK/NG judgment. Ideal to be built into a production line for a laborsaving and a quality control purpose

Variety ranges from F.S.10mL/min to F.S 500L/min are available. Promotes an automation and a laborsaving of the measurement

Helium Leak Tester adopts the new testing method and Helium Leak Tester adopts the new testing method and

All Manometer comes with a traceability. Wide range of Manometers, from a micro pressure (F.S. 200Pa) to a high pressure (F.S. 50MPa) are available

Peripheral instruments are used with Air Leak Tester in order to enhance its functionality and convenience

We determine the acceptability of the sounds and vibrations of products using our special analyses developed in-house.

Materials combining unprecedented flexibility and durability

Influence of noise generated during the test on the workpiece can be compensated, reducing the test time

|

DPS | Resolution | 1 Pa | |

| Display Range | ±9.999kPa (Accuracy guaranteed range ±10kPa) | ||

| Accuracy | ±5% of rdg ±1Pa (500Pa or lower: ±2Pa) | ||

| Proof Pressure | 20 MPa | ||

|

Unit |

Test Pressure | kPa, MPa | |

| (kg/cm2, PSI, bar, mmHg, etc) | |||

|

Leak | Pa, kPa, mL/s, mL/min, L/min, Pa・m3/s, | ||

| E-3 Pa・m3/s, Pa/s, Pa/min, *Pa/s, *Pa/min | |||

| (mmH2O, mmHg, inH2O, etc) | |||

| K(Ve) |

mL, L (in3, ft3) | ||

| (Leak Coefficient) | |||

| Leak Display | 4 digits, Sampling rate: 10 times/sec | ||

| Leak Limit | Up to ±999.9Pa | ||

| No# of Channels | 32ch (0 to 31) | ||

| Timer | 999.9 sec (Resolution 0.1 sec) | ||

| Power Source | AC100~240V±10%, 50/60Hz,70VA max | ||

| Ambient Temperature | 5 to 45 ℃ | ||

| Humidity | 80 %RH or less / No dew condensation | ||

|

Weight | Controller: approx. 2.6 kg Pneumatic Unit: approx. 15 kg | ||

| Pressure Source | Clean and dry air. Source pressure must be sufficiently higher than the test pressure | ||

| Pilot Pressure | Clean and dry air, regulated between 500 to 700kPa | ||

|

Connecting Port | Pilot pressure:Rc1/4 | ||

| Test pressure:Swagelok Ф6mm (WORK & MASTER port) | |||

| CPU | SH-2A 144MHz, DRAM8MB | ||

|

RS-232C (D-sub 9 pins) | I/F fixed length | Test parameters as well as test results are transmitted | |

| ID/F fixed length | |||

| T/F fixed length | Only test results are transmitted | ||

| Others | Special formats | ||

|

USB Port |

Test Data | Judgment, Leak, Test pressure, Channel#, Timers etc. | |

| Test Parameter | Test parameters of all setting screens | ||

|

Standard Accessories | Pilot pressure filter regulator, Quick mounting brackets, | ||

| Control I/O connector, Power cable, Inspection record, | |||

| Operation manual CD, Traceability documents | |||

LS-R740SH- ①②③

| ① | Test Pressure | Super High Pressure 10MPa | H100 | Range 5.0 to 10.0MPa (PS 10MPa) |

| Super High Pressure 16MPa | H160 | Range 5.0 to 16.0MPa (PS 20MPa) | ||

| ② | Option | Nylon Filter Housing | RX02 | Filter housing for the pilot pressure port is nylon |

| NPT Fittings | PX1 | The screw of connecting port is NPT1/4 | ||

| Panel Mount | P | Controller is designed to be p an el-mounted | ||

| ③ | Cable Length | Unit-to-Unit 3m | S3 | Standard |

| Unit-to-unit 5m | S5 | Option | ||

| Unit-to-unit 10m | S10 | Option |

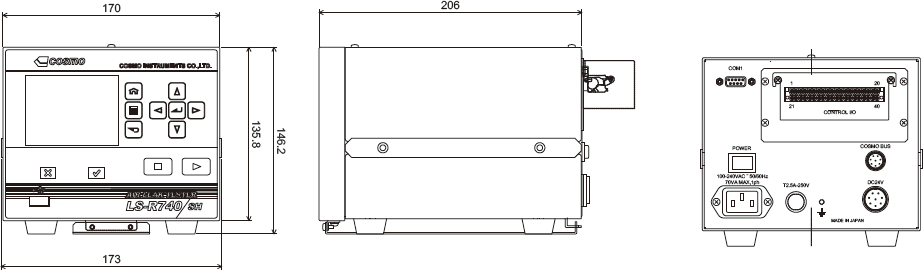

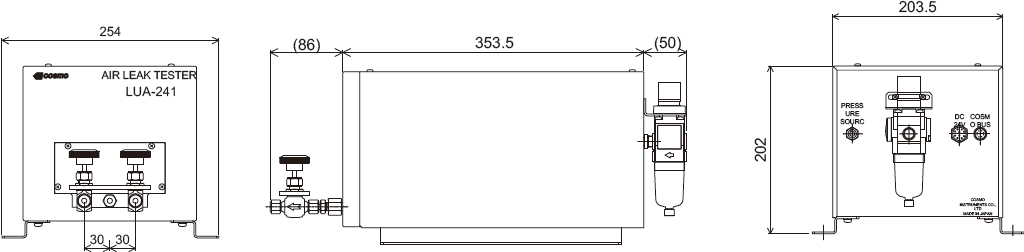

Controller

Pneumatic Unit

Unveiling a new chapter — the grand inauguration of our Head Office is successfully complete.

Started a new venture manufacturing plant at Bengaluru.

⚡ EV Summit | 22 Aug 2025 | New Delhi – Driving the future of electric mobility!

© Copy Rights 2024 Cosmo Instruments India Pvt. Ltd.