Feature 1

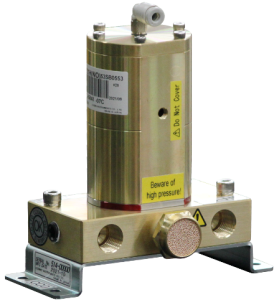

The specially designed air-operated valve prevents leaks, small volume change, and temperature change that could cause errors in leak test.

Feature 2

To prevent the malfunction of the exhaust valve due to dust, the sliding part and the detection circuit are separated from each other.

The ports to be connected to the tested part and the master are provided with special filters.

Feature 3

Since large flow can be used, there is almost no effect on the pressurization time and exhaust time for the tested part.

Feature 4

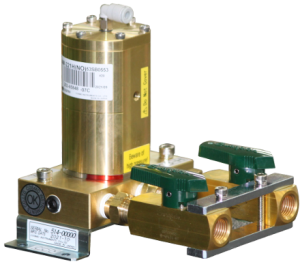

The integrated structure enables air to be exhausted simultaneously on the tested part and master sides.

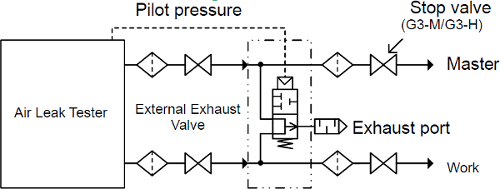

The External Exhaust Valve is controlled by the leak tester with the option of External Exhaust Valve.

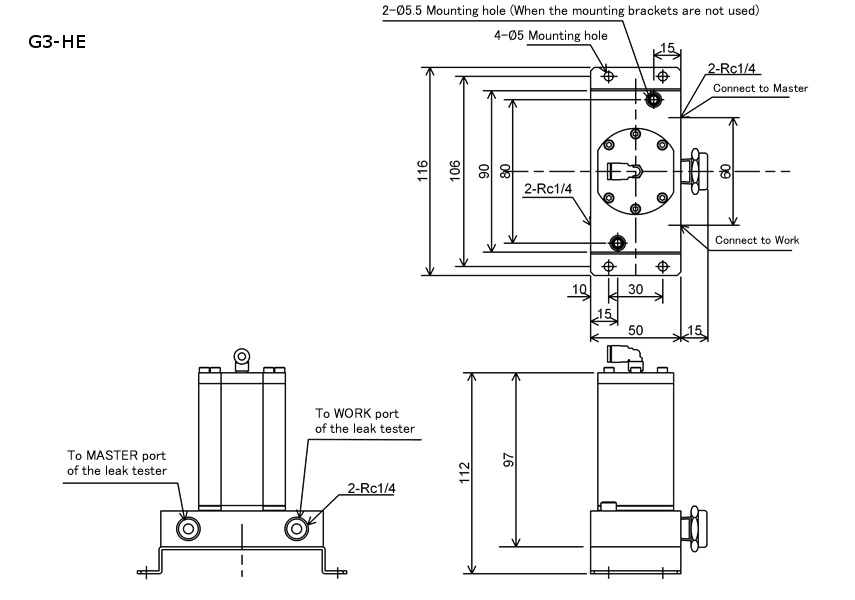

Pneumatic Circuit

- The length of the pilot pressure pipe must be up to 3 m. Otherwise, malfunctions could occur.

- Install the External Exhaust Valve horizontally, as close to the tested part (Work) as possible and lower than the leak tester.