Air Leak Tester is the automatic leak detector detects any leaks by the minute change of differential pressure and conducts OK/NG judgment. Ideal to be built into a production line for a laborsaving and a quality control purpose

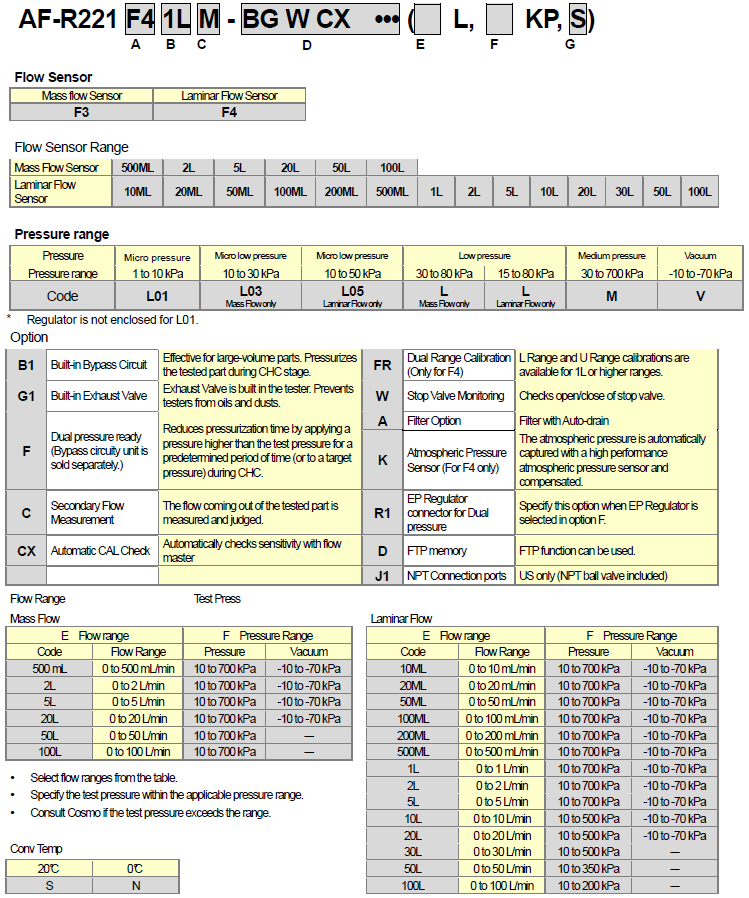

Variety ranges from F.S.10mL/min to F.S 500L/min are available. Promotes an automation and a laborsaving of the measurement

Helium Leak Tester adopts the new testing method and Helium Leak Tester adopts the new testing method and

All Manometer comes with a traceability. Wide range of Manometers, from a micro pressure (F.S. 200Pa) to a high pressure (F.S. 50MPa) are available

Peripheral instruments are used with Air Leak Tester in order to enhance its functionality and convenience

We determine the acceptability of the sounds and vibrations of products using our special analyses developed in-house.

Materials combining unprecedented flexibility and durability

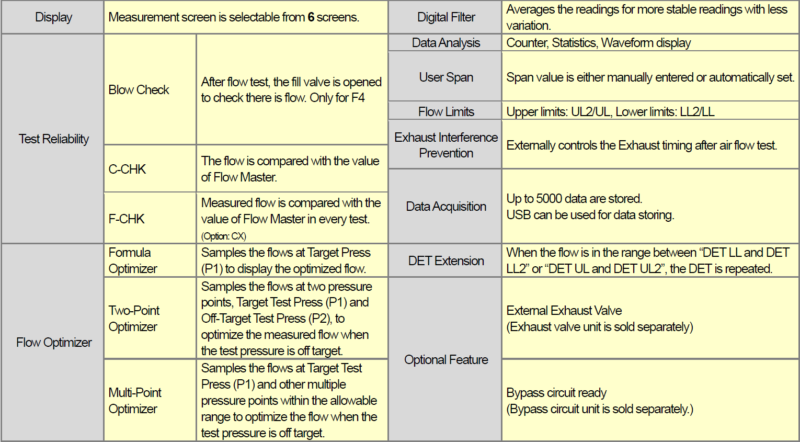

| Pressure media | Air | Connecting port | Pressure source, Pilot pressure:Rc 1/4 Laminar Flow model 100L only: Rc 3/8

WORK port:200L/min or less: Rc 1/4 | |

| Accuracy | *Laminar Flow Sensor ±1.5% of F.S. ±1 digit (At specified pressure) | |||

| *Mass Flow Sensor ±1.5% of F.S. ±1 digit (At specified pressure) ±3% of F.S. ±1 digit (At non-specified pressure) | ||||

| RS-232 | Front panel port | Fixed length output: T, IL, ML, D, P, F2 | ||

| Specified test pressure range | Micro (L01): 1 to 10kPa Micro low (L03): 10 to 30kPa (Mass Flow only) Micro low (L05): 10 to 50kPa (Laminar Flow only) Low (L): 15 to 80kPa Medium (M): 3to 700kPa Vacuum (V): -10 to -70kPa (20L or less) | Rear panel port | Fixed length output: T, IL, ML, D, P, F2 | |

| Test Data | Flow, Pressure, Comp value, Air temp, Flow limits, Atm press, and others | |||

| CSV Copy to USB | CSV file | |||

| USB Port | Parameter backup System backup Software version update | |||

| Channels | 32ch (0~31) | |||

| Power supply | AC100 to 240V ±10%, 50/60Hz, 60VA max (Power cable included is for AC125V only) | |||

| Flow Unit | L/min, mL/min, L/s, mL/s, L/h, m3/h, mm3/s, USP(User Span) | |||

| Timer setting | 999.9 sec (min 0.1sec) | |||

| Pressure Unit | kPa, MPa, (psi, kg/cm2, bar, mbar, mmHg, cmHg, inHg, mmH2O) | |||

| Pressure source | Clean and dry air. Pressure source should be higher than the test pressure | |||

| Standard and accessories | Quick connection fittings, I/O connector, Power cable (3m), Inspection record, Traceability documents and Operation manual | |||

| Ambient temperature | 5 to 45℃ | |||

| Humidity | Max. 80%RH and no condensation | |||

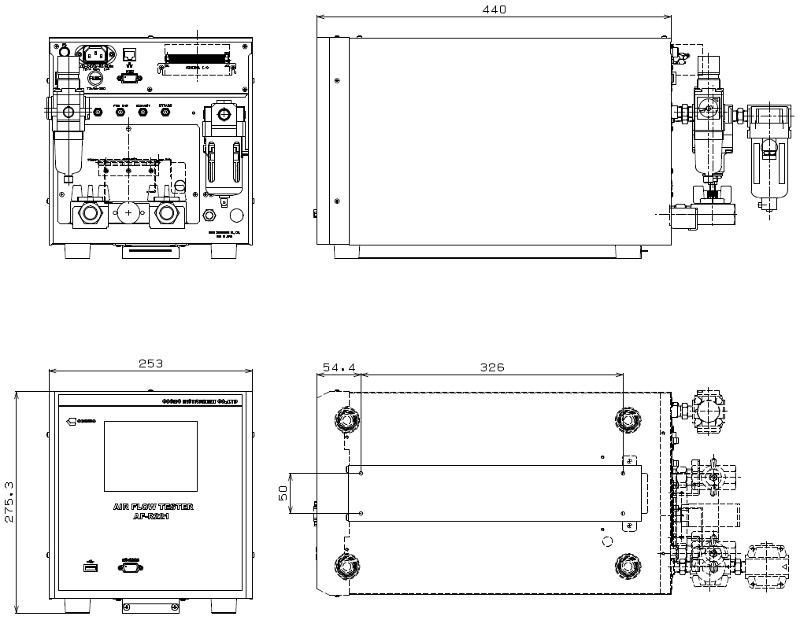

| Weight | Approx. 15kg | |||

Unveiling a new chapter — the grand inauguration of our Head Office is successfully complete.

Started a new venture manufacturing plant at Bengaluru.

⚡ EV Summit | 22 Aug 2025 | New Delhi – Driving the future of electric mobility!

© Copy Rights 2024 Cosmo Instruments India Pvt. Ltd.