Air Leak Tester is the automatic leak detector detects any leaks by the minute change of differential pressure and conducts OK/NG judgment. Ideal to be built into a production line for a laborsaving and a quality control purpose

Variety ranges from F.S.10mL/min to F.S 500L/min are available. Promotes an automation and a laborsaving of the measurement

Helium Leak Tester adopts the new testing method and Helium Leak Tester adopts the new testing method and

All Manometer comes with a traceability. Wide range of Manometers, from a micro pressure (F.S. 200Pa) to a high pressure (F.S. 50MPa) are available

Peripheral instruments are used with Air Leak Tester in order to enhance its functionality and convenience

We determine the acceptability of the sounds and vibrations of products using our special analyses developed in-house.

Materials combining unprecedented flexibility and durability

With Mass Flow sensor equips, no need to correct temperature and pressure.

Highly responsive sensor instantly measures the flow rate

Multi-function display is ideal for various measurements

| The number of Channels | 10 Channels available |

|---|---|

| Upper/Lower Limit | 4 levels (HH, HI, LO, LL) |

| Zero Adjustment | One-push zero adjusting method |

| Auto Zero | Auto Zero button |

| Display Hold | Hold button |

| Display Response | Digital filter (High, Medium, Low) |

| RS-232C | 1200, 9600, 19200bps switchable |

| BCD output | Open collector |

| Display Digits | 3.5 digits (1999) / 4.5 digits (19999) |

| Sampling Time | 250ms/50ms switchable |

| User Span | 0.001~9,999 (Default 1.000) |

| Flow range | 500 mL/min 2, 5, 20, 50, 200, 500 L/min | |

|---|---|---|

| Pressure media | Air(*1) and specified gases(*2) | |

| Accuracy | F.S. up to 20% | ±3% of rdg ±1 digit 200,500L/min : ±5% of rdg ±1 digit |

| F.S. 20% or less | ±1% of F.S. ±1 digit | |

| Ambient temperature | 0 to 50℃ (Accuracy is guaranteed only for +10 to 35℃) | |

| Pressure Range | ‘-70kPa to 1MPa 200,500L/min : -35kPa to 1MPa | |

| Withstand Pressure | 1.5MPa | |

| Response | Approx. 300ms/step response 99% | |

| Pressure Loss | Up to 2kPa | |

| Pressure connection port | 50mL/min or less : Rc(PT)1/4 200mL/min or more : Rc(PT)1/2 | |

| Power source | 24VDC ±10%, 0.3A max (AC Adaptor is included) | |

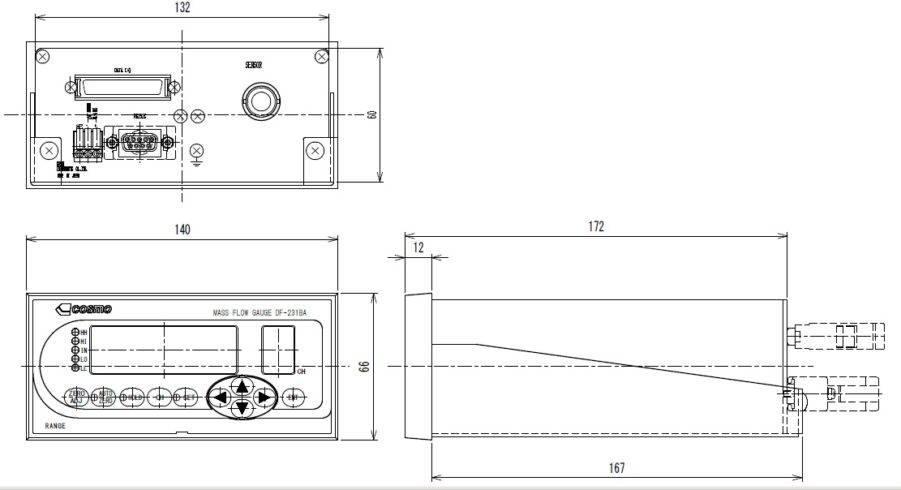

| Dimensions | Display W140×H66×D172 | |

| Panel Cutting | Cutting Size : W133xH61 mm | |

| Documents | Traceability documents, Operation manual | |

| (1) Flow Range | (2) Option | (3) Power Source | ||||

| Code | Measurement Range | Display | Code | Description | Code | Description |

| 500ML | 0~500mL/min | 000~500 | F1 | 5V Analog Output | VG | AC adaptor, 100V cable 3m |

| 2L | 0~2L/min | .000~1.999 | F2 | 10V Analog Output | VH | AC adaptor, 240V cable 2m |

| 5L | 0~5L/min | 0.00~5.00 | VJ | Without AC adaptor | ||

| 20L | 0~20L/min | 0.00~19.99 | ||||

| 50L | 0~50L/min | 00.0~50.0 | ||||

| 200L | 0~200L/min | 00.0~199.9 | ||||

| 500L | 0~500L/min | 000~500 | ||||

Unveiling a new chapter — the grand inauguration of our Head Office is successfully complete.

Started a new venture manufacturing plant at Bengaluru.

⚡ EV Summit | 22 Aug 2025 | New Delhi – Driving the future of electric mobility!

© Copy Rights 2024 Cosmo Instruments India Pvt. Ltd.