Quick Access

Directly access the screen of some screen you often to use.

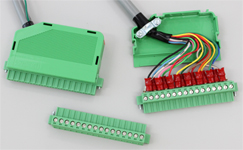

Fieldbus(Option)

I/O wiring is completed with dedicated cable connectors.Supports smooth communication with PLC with fewer cables.Test results can be output to the network.

Simple to operate with icons.

The menu screen is easily displayed with an icon.

The Home icon can move directly to the measurement screen, and the (i) icon in the upper left displays all sort of information.

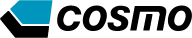

Can switch between 6 kinds of measurement screen

The measurement screen is available in 6 different types for different applications/situations, including a simple display and a detailed display.

Also, the display items can be customized.

Each type of settings screen

During setup, a large numeric keypad appears, and all types of settings can be adjusted using the simple screen display.

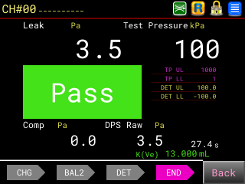

A complete help screen and help display

In the help screen, complete explanations of computational tools and peripheral devices are available.

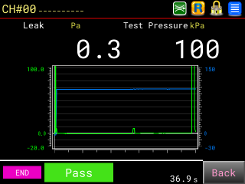

Waveform monitor function for test pressure/DP (leak volume)

Displays the test pressure and DP waveforms from measurement start to detection completion.

The ideal time for applying pressure and attempting detection can be found.

Phoenix Contact product is used for input/output connector

Phoenix Contact product was adopted for the connector of the input/output interface.

The connector is very reliable, and the wiring work can be done with a flat-head screwdriver, so that the work efficiency increases.

Automatic setup function

Several setting are necessary for the leak test.

This function provides initial settings for measurement time when first implementing the leak test.

Easy data collection with USB port

Measurement data is automatically saved to USB memory.

Other settings information can also be backed up with USB memory.

Waveform Pneumatic Circuit Diagnosis

Checks for anomalies in the air circuit with workpiece at each operation.

(Attention) Effectiveness varies based on operating conditions, and there are cases when it cannot be used.

Function for switching between display of multiple languages

Supports Japanese, English, Chinese, Korean, German, Spanish, and Portuguese.

Overseas expansion is simple.

Performance improvement function

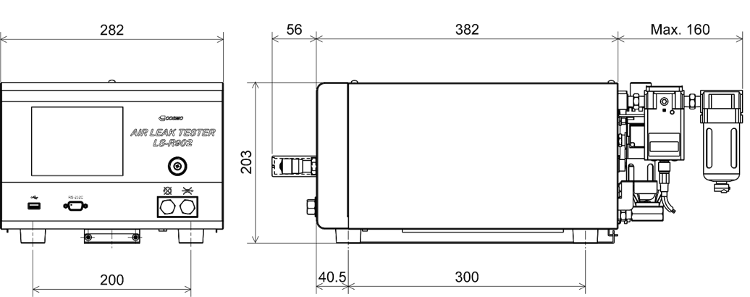

■ Model LS-R902(ABC.D.E)

A, B, D and E in the model notation are mandatory.

| Pneumatic |

Circuit | Intelligent 1 Pneumatic Circuit | A1 | Large flow circuit with great sensor protection features |

|---|

| Intelligent 2 Pneumatic Circuit | A2 | Equipped with an equalization valve and additional self-check features to A1 circuit |

|---|

| Micro Volume Circuit | AS01 | For the parts whose volume is approx.

10 mL or smaller and the leak specifications are quite small. |

|---|

| Small Volume A1 Circuit | AS1 | For the parts whose volume is approx.

100 mL or smaller and high detection performance is required. |

|---|

| Secondary Pressure Circuit *1 | C | For external pressure (secondary pressure) test |

|---|

| B | Test Pressure

Range | Precision Regulator | Medium pressure | M | Test pressure range 50 to 800 kPa

(PS 1 MPa, Regulator 0.8 MPa) |

|---|

| Low pressure | L | Test pressure range 10 to 100 kPa

(PS 100 kPa, Regulator 200 kPa) |

|---|

| Micro pressure | L02 | Test pressure range 5 to 20 kPa

(PS 20 kPa, Regulator 200 kPa) |

|---|

| Vacuum pressure | V | Test pressure range -5 to -100 kPa

(PS -100 kPa, Regulator -100 kPa) |

|---|

| High pressure *2 | H20 | Test pressure range 2.0 MPa or less

(PS 2 MPa, Without regulator) |

|---|

| E/P Regulator | Medium pressure | MR | Test pressure range 50 to 800 kPa

(PS 1 MPa, Regulator 0.9 MPa) |

|---|

| Low pressure | LR | Test pressure range 10 to 95 kPa

(PS 100 kPa, Regulator 100 kPa) |

|---|

| Vacuum pressure | VR | Test pressure range -5 to -75 kPa

(PS -100 kPa, Regulator -80 kPa) |

|---|

| C | Option | External Exhaust Valve Ready *3 | G | External Exhaust Valve is sold separately. |

|---|

| Come with Cal driving valve for Leak Master | J | Come with Cal driving valve.

Leak Master is sold separately. |

|---|

| Bypass Circuit Ready | Without regulator | B | Bypass Circuit Unit is sold separately. |

|---|

| With regulator | B1 |

|---|

| Come with Stop Valve Open/Close Check Switch | W | Equipped with function to monitor Stop Valve opening/closing |

|---|

| Pressure/Vacuum Pressure Sensor | PV1 | Equipped with a Pressure/Vacuum pressure sensor

Low pressure: ±100 kPa Medium pressure: -100 to 1000 kPa |

|---|

Without Precision Regulator

(L, M, V press) | E1 | Without Precision Regulator |

|---|

| Blow Orifice Ø 1.2 *4 | F1 | Standard orifice changed from Ø 3.2 to Ø 1.2 |

|---|

| E/P Regulator Ready | R1 | E/P Regulator Ready With Output Connector |

|---|

| Nylon Filter Housing | RX02 | Filter housing for the pilot pressure port is nylon. |

|---|

| RX03 | Filter housings for the pilot pressure and test pressure ports are nylon. |

|---|

| Filter Replacement | RX06 | Pilot Pressure Port Comes with Filter Only |

|---|

| DPS 10 kPa | D4 | Sensor range: ±10 kPa Resolution: 1 Pa |

|---|

| NPT Fittings | PX1 | NPT Fittings |

|---|

| Rechargeable Battery *5 | PX2 | Rechargeable battery replacing the button cell (Not CE compliant) |

|---|

| D | Units | UX1 | SI units (For Japan) |

|---|

| UX2 | All units (For overseas only) |

|---|

| E | Power Cable | VA | 125 V (3 m) |

|---|

| VE | 250 V (2 m)m |

|---|

| VK | 250 V (2 m) (Only for Chinese customers) |

|---|

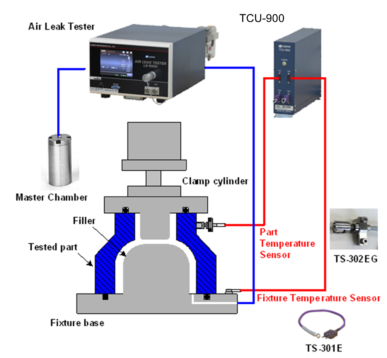

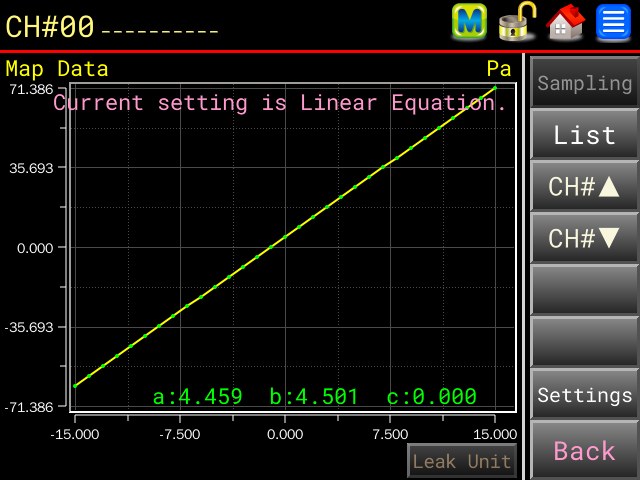

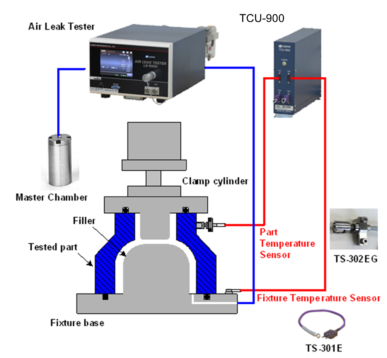

Helps reduce measurement errors and false rejects due to part temperature effects.

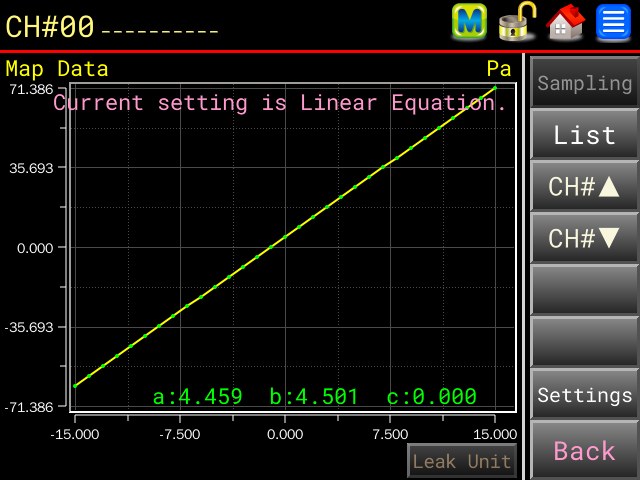

Compensation graphs viewed on large LCD screen.

Easy setting for mapping of the graphs.

Temperature compensation mapping should be adjusted on the actual production line.

The temperature difference between the part and the environment is measured to carry out the Temperature Compensation according to the correlation between the temperature difference and measurement errors.

Major applications

Post-cleaning leak tests, engine parts (cylinder head, cylinder block)

(a correlation should exist in the differential pressure between the temperature of Work and the applied air)

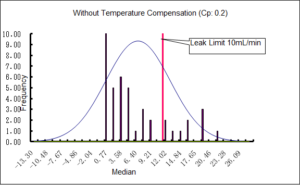

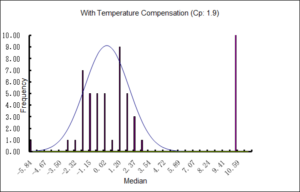

Example of Temperature Compensation Data

| Tested part | Oil pan (Whole) |

| Test pressure | 100kPa |

| Equivalent internal volume | 2500 mL |

| Leak specification | 10 mL/min |

| Test timers | Pressurization 22 secs.

Equalization 3 secs.

Stabilization 5 secs.

Detection 3 secs. |