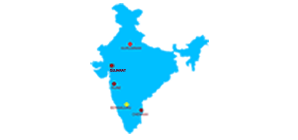

Sophisticated Air Flow Tester AF-R220

AF-R220

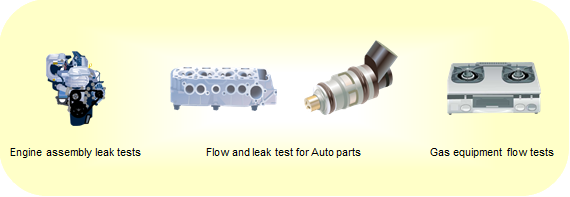

Edge & Function

Display of Equivalent flow rate at 1 atm, 20℃ (when option K is selected, the actual atmospheric pressure is automatically measured for the calculation)

Take advantages of 2 different flow sensor

Laminar Flow Sensor

*Wide variety of ranges (F.S. 10mL/min to 100L/min)

*Allows measurement of discharge flow rate of pulsative parts such as pumps

*Durable and robust with no moving part

Mass Flow Sensor

*Allows measurement with different/variable test pressure

*No temperature compensation required

*No atmospheric compensation required

*High response speed

With USB port available, data collection or data back-up can be easily carried out

Main features

*Test data collection

*Waveform data collection

*Parameter backup/restore

*System backup/restore

*Copy CSV to USB

*Software version update

*Copy Operation manual

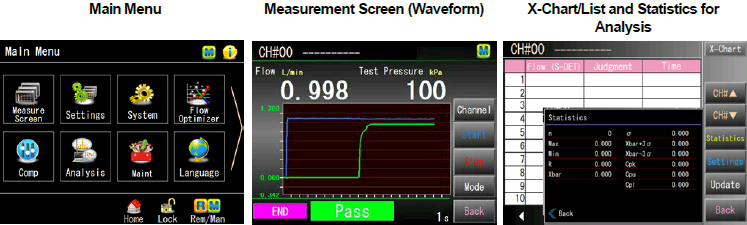

| Display | Display6Measurement screen is selectable from 6 different screens | Data Acquisition | Up to 5000 data are stored. USB can be used for data storing | |

| Test Reliability | Sensor Protection | The pneumatic circuit is cleaned at the end of every flow test | Data Analysis | Counter, Statistics, Waveform display |

| User Span | Span value is either manually entered or automatically setup | |||

| Blow Check | After the flow test, the fill valve is opened to check if there is flow or not | |||

| Exhaust Interference Prevention | Exhaust timing will be controlled for the cases where multiple tests are preformed at the same time | |||

| Digital Filter | Averages the readings for more stable readings with less variation | |||

| C-CHK | The flow is compared with the values of Flow master | |||

| Equivalent Flow Display | The flow rate when air is flown in an environment of 1 atm at 20℃. When the option K is selected, this feature can be automatically used | |||

| F-CHK | The measured flow is compared with the value of Flow master in every test (Option: CX) | |||

| Flow Limits | Upper limits (UL2/UL), Lower limits (LL2/LL) | |||

| Flow Optimizer | Formula Optimize | Samples the flows at Target Test Press(P1) to display the optimized flow | DET Extension | When the flow is in the range between "S-DET LL and S-DET LL2" or "S-DET UL and S-DET UL2", DET stage will be repeated |

| Two-Point Optimizer | Samples the flows at two pressure points, Target Test Press(P1) and Off-Target Test Press(P2), to optimize the measured flow when the test pressure is off target | Option Features | External exhaust valve (Exhaust valve unit is sold separately) | |

| Multi-Point Optimizer | Samples the flow at Target Test Press(P1) and other multiple pressure points within the allowable range to optimize the flow when the test pressure is off target | Bypass circuit ready (Bypass circuit unit is sold separately) | ||

Spec

| Pressure media | Air | Connecting port | Pressure source, Pilot pressure:Rc 1/4 Laminar Flow model 100L only: Rc 3/8 WORK port:200L/min or less: Rc 1/4 |

|

| Accuracy | *Laminar Flow Sensor ±1.5% of F.S. ±1 digit (At specified pressure) |

|||

| *Mass Flow Sensor ±1.5% of F.S. ±1 digit (At specified pressure) ±3% of F.S. ±1 digit (At non-specified pressure) |

||||

| CPU | ARM9 400 MHz, DRAM 128 MB | |||

| RS-232 | Front panel port | Fixed length output: T, IL, ML, D, P | ||

| Specified test pressure range | Micro (L01): 1 to 10kPa (Regulator is not enclosed) Micro low (L03): 10 to 30kPa (Mass Flow only) Micro low (L05): 10 to 50kPa (Laminar Flow only) Low (L): 30 to 80kPa Medium (M): 3to 700kPa Vacuum (V): -10 to -70kPa (20L or less) |

Rear panel port | Fixed length output: T, IL, ML, D, P | |

| Test Data | Flow, Pressure, Comp value, Air temp, Flow limits, Atm press, and others | |||

| CSV Copy to USB | CSV file | |||

| USB Port | Parameter backup System backup Software version update Copy Operation manual (PDF) |

|||

| Channels | 32ch (0~31) | |||

| Power supply | AC100 to 240V ±10%, 50/60Hz, 60VA max (Power cable included is for AC125V only) |

|||

| Flow Unit | L/min, mL/min, L/s, mL/s, L/h, m3/h, USP(User Span) | |||

| Timer setting | 999.9 sec (min 0.1sec) | |||

| Pressure Unit | kPa, MPa, (psi, kg/cm2, bar, mbar, mmHg, cmHg, inHg, mmH2O) | |||

| Pressure source | Clean and dry air. Pressure source should be higher than the test pressure | |||

| Standard and accessories | Quick connection fittings, I/O connector, Power cable (3m), Inspection record, and Operation manual | |||

| Ambient temperature | 5 to 45℃ | |||

| Humidity | Max. 80%RH and no condensation | |||

| Weight | Approx. 15kg | |||

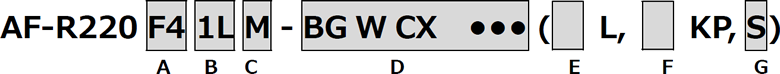

Classification

| A Flow Sensor | |

| Mass Flow Sensor | Laminar Flow Sensor |

| F3 | F4 |

| B Flow Sensor Range | ||||||||||||||

| Mass Flow Sensor range | 500ML | 2L | 5L | 20L | 50L | 100L | ||||||||

| Laminar Flow Sensor range | 10ML | 20ML | 50ML | 100ML | 200ML | 500ML | 1L | 2L | 5L | 10L | 20L | 30L | 50L | 100L |

| C Test Pressure range | ||||||

| Test Pressure | Micro | Micro-low | Micro-low | Low | Medium | Vacuum |

| Test Pressure range | 1 ~ 10kPa | 10 ~ 30kPa | 10 ~ 50kPa | 30 ~ 80kPa | 30 ~ 700kPa | -10 ~ -70kPa |

| Code | L01 | L03 Mass Flow only |

L05 Laminar Flow only |

L | M | V |

- Regulator is no enclosed for L01

| D Option | |||||

| B1 | Built-in Bypass Circuit | Effective for large-volume parts. Pressurize the tested part during CHG stage. | FR | Dual Range Calibration (For F4 only) | L range and U range calibrations are available for 1L or higher ranges |

| G1 | Built-in Exhaust Valve | Exhaust valve is set in the tester. Prevents testes from oils and dusts | W | Stop Valve Monitoring | Checks open/close of stop valve |

| F | Dual Pressure ( Bypass circuit unit is sold separately) | Reduces pressurization time by applying a pressure higher than the test pressure for a predetermined period of time (or to a target pressure) during CHG. | A | Filter Option | Filter with Auto-drain |

| C | Secondary Flow Measurement | The flow coming out of the tested part is measured and judged. | K | Atmospheric Pressure Sensor (For F4 only) | The atmospheric pressure is automatically captured with a high performance atmospheric pressure sensor and compensated |

| R1 | Dual Pressure EP Regulator connector | F Specify this option when EP regulator is selected in option F | PX2 | Battery Option | Rechargeable battery. The rechargeable battery does not conform to CE |

| CX | Automatic CAL Check | Automatically checks sensitivity with flow master | |||

| E Flow Rage | F Test Pressure | |||||||||

| Mass Flow Sensor | Laminar Flow | |||||||||

| E Flow Range | F Test Pressure | E Flow Range | F Test Pressure | |||||||

| Code | Flow Rage | Positive Pressure | Negative Pressure | Code | Flow Rage | Positive Pressure | Negative Pressure | |||

| 500ML | 0 ~ 500 mL/min | 10 ~ 700kPa | -10 ~ -70kPa | 10ML | 0 ~ 10 mL/ min | 10 ~ 700kPa | -10 ~ -70kPa | |||

| 2L | 0 ~ 2 L/min | 10 ~ 700kPa | -10 ~ -70kPa | 20ML | 0 ~ 20 mL/ min | 10 ~ 700kPa | -10 ~ -70kPa | |||

| 5L | 0 ~ 5 L/min | 10 ~ 700kPa | -10 ~ -70kPa | 50ML | 0 ~ 50 mL/ min | 10 ~ 700kPa | -10 ~ -70kPa | |||

| 20L | 0 ~ 20 L/min | 10 ~ 700kPa | -10 ~ -70kPa | 100ML | 0 ~ 100 mL/ min | 10 ~ 700kPa | -10 ~ -70kPa | |||

| 50L | 0 ~ 50 L/min | 10 ~ 700kPa | — | 200ML | 0 ~ 200 mL/ min | 10 ~ 700kPa | -10 ~ -70kPa | |||

| 100L | 0 ~ 100 L/min | 10 ~ 700kPa | — | 500ML | 0 ~ 500 mL/ min | 10 ~ 700kPa | -10 ~ -70kPa | |||

| * Select the flow range from the lists shown above

* Specify the test pressure within each pressure range * Consult Cosmo for unspecified ranges |

1L | 0 ~ 1 L/min | 10 ~ 700kPa | -10 ~ -70kPa | ||||||

| 2L | 0 ~ 2 L/min | 10 ~ 700kPa | -10 ~ -70kPa | |||||||

| 5L | 0 ~ 5 L/min | 10 ~ 700kPa | -10 ~ -70kPa | |||||||

| 10L | 0 ~ 10 L/min | 10 ~ 700kPa | -10 ~ -70kPa | |||||||

| G Conversion temperature | 20 L | 0 ~ 20 L/min | 10 ~ 700kPa | -10 ~ -70kPa | ||||||

| 30 L | 0 ~ 30 L/min | 10 ~ 700kPa | — | |||||||

| 20 °C | 0 °C | 50 L | 0 ~ 50 L/min | 10 ~ 500kPa | — | |||||

| S | N | 100 L | 0 ~ 100 L/min | 10 ~ 500kPa | — | |||||

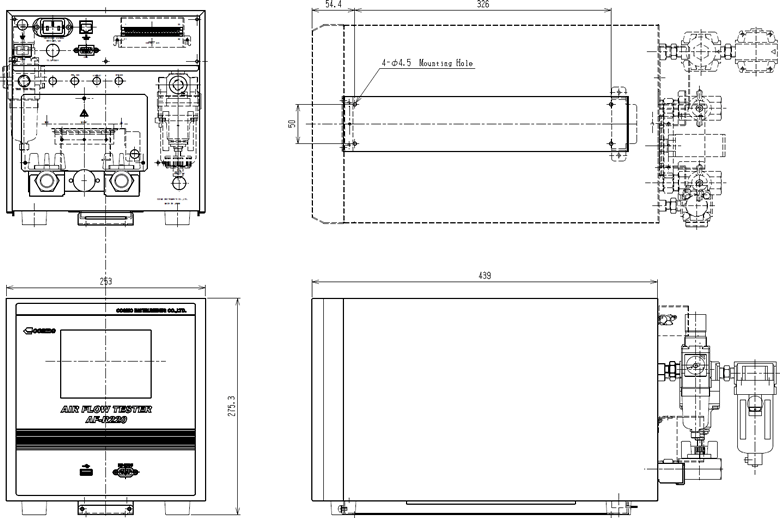

Appearance